Electronic Assembly & Testing

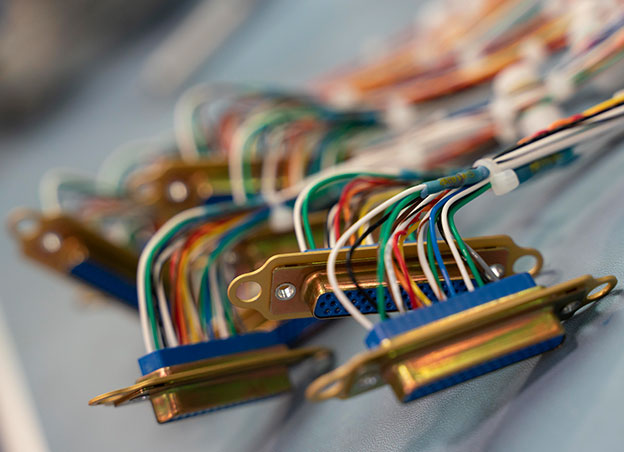

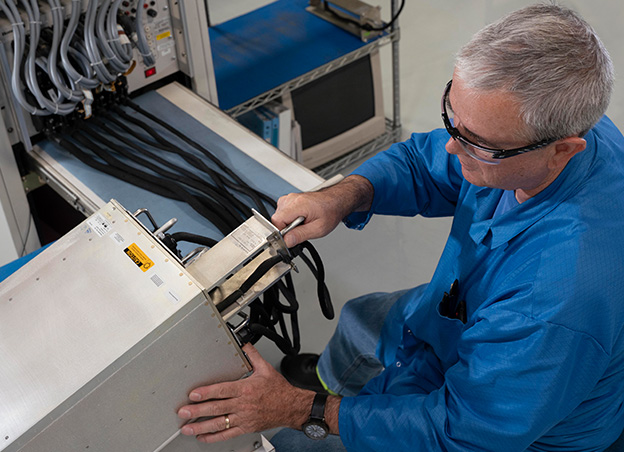

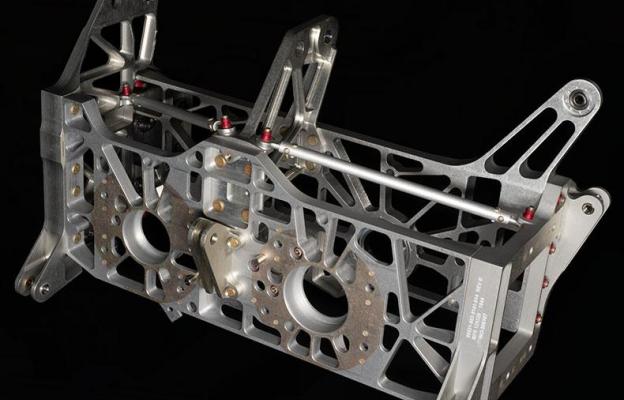

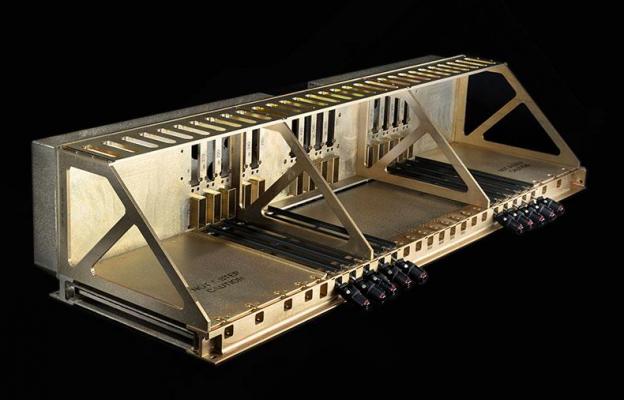

The electromechanical and integration capabilities at The Atlas Group include building housings, running wires and motherboard circuit-assembly installations to deliver a complete, installable product.

This capability is cross-departmental and coordinates with aircraft structures, flight science, electrical systems engineering, systems safety, project engineering, product support and multiple testing procedures within The Atlas Group.

Every electronic build is tested and held to the rigorous standards we uphold for the aerospace and defense industry. The testing performed is industry and customer-specific for miswire, misfire, leakage high-pot and continuity. Any new build within our electromechanical group is controlled and process-driven for future success rates in production.

Our philosophy of vertical integration means that customers can enjoy single-source service for electronic assemblies. The Atlas Group provides true start-to-finish manufacturing, from materials to engineering, testing to production, all within budget and deadline.

- Wire wrap

- Wire harness

- Electromechanical integration

- Soldering

- Potting

- Conformal coating

- Stress and functional testing

Learn more about the companies that make up The Atlas Group.