Putting Innovation Together

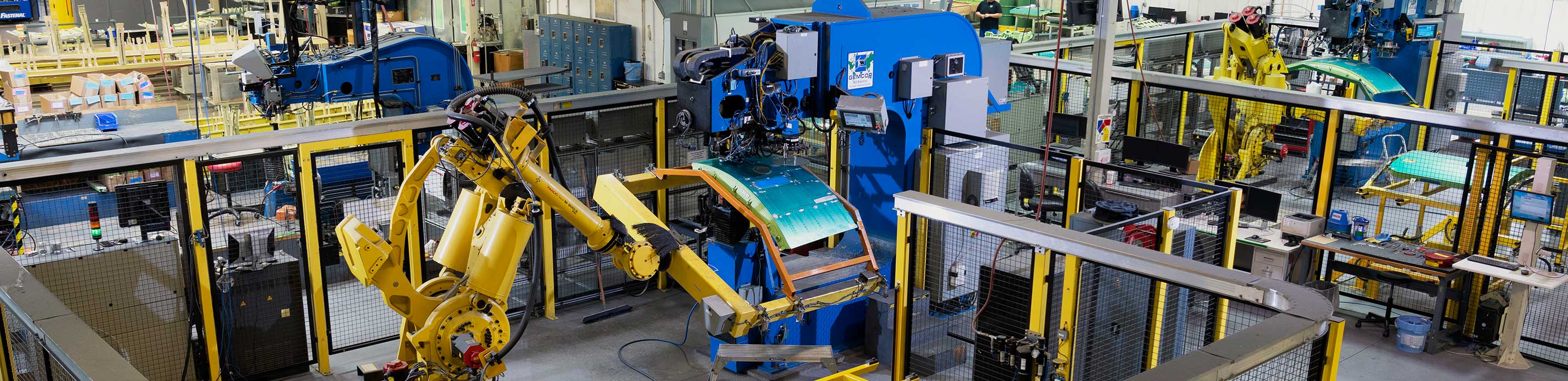

Advances in integration have revolutionized industries and businesses across the world, but perhaps none more so than the aerospace and defense sectors. Experience has shown that even incremental improvements in core processes yield results in efficiency, quality and cost-effectiveness. The Atlas Group is an industry leader in utilizing vertical integration and creating innovative best practices.

The Atlas Group's vertically integrated capabilities address current industry trends while preparing for the future with a focus on advanced technology, superior equipment, forward-leaning engineering and lean manufacturing led by a well-educated and tenured workforce. The results across all of The Atlas Group's core competencies are lower costs, quicker turnaround and absolutely reliable service from start to finish.

Customers of The Atlas Group can confidently rely on our abilities to meet and exceed the highest standards in the industry. The wide scope of capabilities encompassed by The Atlas Group's suite of companies provides a unique opportunity for start-to-finish service and a single-source customer experience.

- Complex Assembly

- Precision Machining

- Sheet Metal Fabrication

- Skin Manufacturing

- Electronic Assembly & Testing

- Chemical Milling & Phosphoric Acid Anodizing

- Metal Bonding

- Spares & Emergent

Learn more about the companies that make up The Atlas Group.